Acorn Web Offset

Acorn is a specialist printer of A4 and A5 size, multi-pagination magazines, producing over 300 periodical titles.

Established 45 years and operating from one of the UK’s lowest cost production facilities in West Yorkshire, close to the M1 / A1 / M62 motorway network. We effectively support publishers across the whole of the UK with their printing needs.

From the outset, our experienced sales team is available to help you choose the most innovative and cost effective formats as well as creating a detailed brief for our commercial team to guarantee you a hassle-free experience.

Our friendly customer service executives keep you informed of your magazine’s progress at every step. They are on hand to assist you with the upload and approval of your pages, right through to final despatch. A key measure of our performance is the 98.9% success rate we have with on-time delivery across 15,000 deliveries each year.

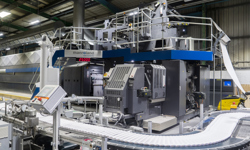

High speed web offset and sheet-fed printing equipment together with in-house saddle stitching, perfect binding and a well-established mailing partnership means we can cope with the most demanding of production turnarounds.

We are ultra-focused on championing print as an effective medium. A series of investments have been implemented to increase efficiency, reduce energy and cut carbon. Our 32pp Lithoman web press is one of the newest in the UK, boasting technology that delivers market-leading paper waste reductions. Two high speed stitching lines have also increased our productivity by 30% and cut any reliance on rising agency labour.

Acorn prides itself on being a responsible company. Building on its ISO 14001, FSC and PEFC accreditations, our recent investments have been specifically focused on reducing our impact on the environment. These include:

- Eco plate processors – 1 million litres of water saved

- Responsive LED factory lighting – 250,000 kw/h electrical consumption saved

- Intuitive paper waste compactors – 10,000 HGV miles saved on collections

- 6 rapid EV chargers installed

In 2024, further energy and labour efficiencies are planned with voltage optimisation to be installed in February and a robotic bundle stacker from April.

We are well known to provide magazine printing solutions on time, every time and in a no-fuss friendly way, but we are also investing to ensure these solutions are sustainable and available to our customers for many years to come.

Please visit our website today to review some of the testimonials from our customers or join in the conversations on our social media pages.