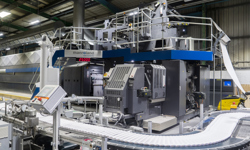

Stephens & George have announced that they have taken delivery of the latest XL106-8P press from Heidelberg. The technology reportedly delivers consistently high quality with steady production speeds of 21,000 sheets per hour.

Investment in the latest technology improves operational efficiencies while demonstrating the company’s commitment to delivering excellence, says Stephens & George. It enables faster turnaround times, helping Stephens & George stay ahead of the curve in a highly competitive marketplace, added the company.

According to Stephens & George, "The operators commented on how quiet the press is, and with the new direct drive feeder, the press is noticeably reducing makeready times.” In addition, to the working conditions around the press, Heidelberg and Stephens & George say they partnered together to reduce spray powder usage on and around the new press by developing a new spray powder system which ensures the working space to be cleaner and spray powder usage reduced.

The press has been built with the highest automation and AI capabilities, lowest waste figures and user experience efficiency, added Stephens & George. The automatic bearing care system reduces maintenance time and delivers more uptime, freeing up over 60 hours per year to deliver further printing output, the company added.

The press has been in full production from day one, added Stephens & George, ever since the Heidelberg service team installed the press in May. “This machine is 15% more productive than the previous presses in use, this could allow to produce over 8 million additional sheets per year, which is equivalent to over 2000 additional sections per year, which makes the Heidelberg Speedmaster the most productive and efficient machine we have ever had,” said Paul Enoch, manufacturing director.

“We believe that Heidelberg equipment is the best in the marketplace,” says Andrew Jones, “and we will always make use of Heidelberg’s latest technology.”

Keep up-to-date with publishing news: sign up here for InPubWeekly, our free weekly e-newsletter.