“We have a mixed portfolio of folders but on this occasion we needed a folder particularly suited to handling lighter weight paper stocks - down to 65gsm - and the Stahlfolder KH 82 ticked all the boxes for our current requirements,” says Kirk Galloway, managing director.

“The KH 82 incorporates a Tremat feeder head and twin suction drums, ensuring each sheet is guided into the side lay very precisely. This is particularly useful for lighter stocks - minimising any mis-feeds and, along with the adjustable side stops, will help prevent any potential play during folding positively contributing to our throughput efficiencies.”

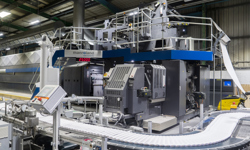

Heidelberg offer a choice of both buckle and combination folders dependent on the mix of work. Buxton’s core business is sectioned paginated work making the small footprint Stahlfolder KH82 combination folder most appropriate, allowing for quicker set-ups, potentially higher running speeds and lower investment costs, says Heidelberg. Used in conjunction with the Palamides stacker which allows product to be offloaded in set quantities or by single sheet facility, it is an easy system for operators to use and one with which Buxton Press personnel are already familiar, several Palamides already being in use at the plant.

Jim Todd, sales director of Heidelberg UK, says: “Buxton Press invests with a business head and with a focus on getting things right for their customers. The Speedmaster XL 106 machines they have taken from us – four eight- and ten-colour presses with CutStar reel to sheeters – have been specified for quality and efficiency so that they can produce magazines to the highest quality, cost-effectively and to tight deadlines. The decision to follow up with this folder purchase shows the emphasis they put on producing work with least delay, waste and risk of marking. It is another investment made to assist their publishing clients.”