Q: What print innovations are you seeing from publishers?

A:

In the current climate, we’re busier than ever helping publishers manage costs. Mainly through basic print principles, such as clever trim sizes, paper choices and efficient page counts.The real innovation from publishers seems to be a shift in their sense of self-worth. Selling advertisements and sponsorship is, of course, always great, but I’ve noticed increased confidence in the way publishers relate to their readers, generating revenue through a strong cover price, slick subscriptions and value packed membership models, which is great to see.

Q: What additional revenue opportunities do you think publishers can take advantage of?

A:

We’re seeing more and more publishers becoming smarter, repurposing their content for books, bookazines and promotional and sponsored products, creating an extra revenue line – recycling in a slightly different way!We’re also seeing this within our free community magazine publishers. Printing notebooks, journals and calendars featuring local landscapes and selling them within the community. Collating a local cookbook including sponsored recipes. When the idea fits the readership and it’s a strong enough proposition, it’s great to see extra revenue generated for our publisher clients.

Q: What is the outlook for paper pricing and what can publishers do about it?

A:

Paper is a hot topic right now. It’s widely reported that paper mills are experiencing strike action which of course is putting extra strain on the working mills. This is having a global impact on availability and prices. Paper requires a lot of energy during the production cycle, and we all know what’s happening with energy prices! The best outcomes are when publishers have an open mind to alternative stocks and trim sizes. If your content is excellent, will your readers really mind if the paper isn’t quite as thick? Could your magazine have more pages, with a tweaked trim size, but cost you less? A careful discussion with your printer about options is a clever idea – it’s not all doom and gloom.Q: How can publishers and printers work more efficiently together?

A:

Your printer should be your friend, or at least considered a virtual team member. It’s in our interest to make you as successful as possible! Open, honest, prompt communication throughout the team is important. Does the ad team know that selling an extra spread pushes the issue size up to an inefficient level? Is the designer aware that having a wider format is costing the business X% extra every issue? Is the owner aware that a tweaked trim size saves print cost and possibly postage costs too? Is everyone aware that using the best FSC, carbon balanced paper is great but sticking a matt laminate on the cover adds plastic to the publication and could make you look a bit hypocritical? Is the production team aware that switching paper stock last minute is not as easy as it used to be? These are all things as printers we’re aware of and hope publishing teams are too, but sadly this isn’t always the case.Q: What can printers do to improve the sustainability of their operations and reduce their impact on the environment?

A:

It’s an ongoing ever-evolving process. Reputable publication printers work incredibly hard in this area: implementing and supporting a robust environmental management system, use of vegetable-based inks, certificated as Zero to landfill and able to offer a wide selection of FSC and carbon-balanced paper. It all requires a dedicated team effort.Q: What can publishers do to reduce the impact on the environment from their magazine production and distribution?

A:

Sustainability goals can be different for individual businesses so it’s best to share your specific aims with your printer.A carefully crafted distribution plan and circulation list is a good start; it sounds obvious but only print what you need! Aim to use a printer that is accredited to 14001 and offers you a broad selection of environmentally sound papers. Advertise your environmental credentials within your magazine and tell your readers how best to recycle it. Paper wrap is a terrific way to show your readers that you’re taking greener steps. The bravest publishers ask about naked mailing but admittedly very few actually take the plunge!

Q: What's in the pipeline at Pensord?

A:

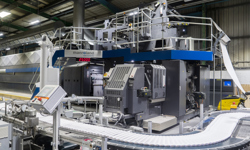

As a specialist magazine printer, we have carefully listened to our clients and we’re excitedly rolling out pioneering digital content solutions to enhance established printed titles. Automated language translation, automated audio conversion and free flow text – all generated directly from publishers’ print files, thereby aiming to deliver extra value for publishers to sell onto their readership, helping to promote inclusivity and to streamline operational costs.In our book division – Cambrian Printers – we’re further boosting our hardback book production capabilities with thread sewing and case binding equipment all under the same roof, producing beautiful high-end publications.

Hopefully having lots of conversations with InPublishing readers.

About us

Pensord Press: A specialist magazine print company for over 50 years, Pensord Press produces over 300 regular titles. Based in South Wales, facilities include some of the most advanced printing, finishing and mailing technology in the UK.

Email: sales@pensordgroup.co.uk

Tel: 01495 223721

Cambrian Printers: Short run, multi-page projects and book printing. Cambrian is a well-equipped specialist in multi-page, high quality books, catalogues and brochures. Perfect Binding, PUR, Thread-sewing and Case-binding all on hand.

Email: sales@pensordgroup.co.uk

Tel: 01970 627111

Pensord Digital: Print runs start at one single copy.

Pensord Design: Creative solutions and outsourced facilities for editorial design and page layout. Designed to complement our printing capabilities.

Email: stuart.moody@pensord.design

Tel: 07525 422065